Take no chances. Inspect the scaffold set up after erection and daily while in use. Don’ remove or allow removal of any parts without the OK from the proper authorities. When wire rope is used, inspect it on each job.

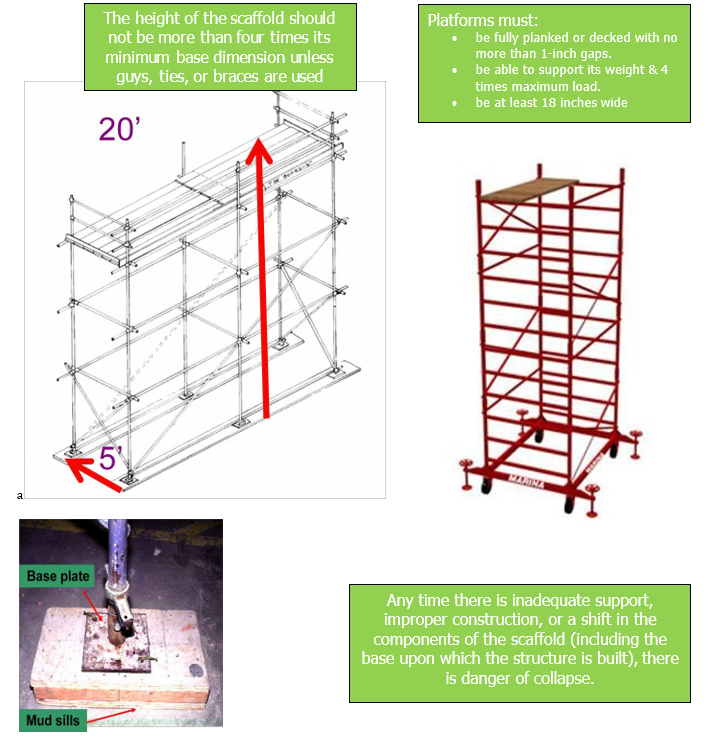

Use base plates, sills, or footers (or combination) on solid ground; make sure scaffold is leveled or plumbed.

Bent or otherwise damaged end frames or braces should not be used. Put them aside for replacement.

Use bracing at all points provided; add extra braces if needed to insure stability.

Scaffolding should be tied to the structure using heavy wire or tie-in devices. The first vertical tie should be at the maximum height of 4 times the narrowest base dimension. Additional ties are not to exceed 26 feet vertically. Maximum horizontal distance between ties is not to exceed 30 feet.

Follow the safe loading capacities as given by the scaffold manufacturer. There’s a limit even to what steel can support. A 4-to-1 safety factor must be figured on scaffolding.

Remember scaffold units are limited in height to 4* times their narrowest base dimension (unless base is widened by outriggers, or more end frames; or tied into building.) Always keep casters locked. (Except to re-spot)

*Exceptions: 3 times in CA, OH, OR, MT, ME 3 ½ time in WA

Use the steps provided on most steel scaffolds to climb up to or down from work levels. Use scaffold climbing ladders where required.

Use overhead canopies to protect workers on lower work levels when work is being done overhead. Rope off unsafe areas underneath scaffold or provide wire mesh around work area.

and toe boards on exposed sides at platform heights of 6 feet or more.

FOLLOW ALL STATE, LOCAL AND FEDERAL CODES, ORDINANCES AND REGULATIONS pertaining to scaffolding because they may be more restrictive. For example, height or width requirements may vary.

SURVEY THE JOB SITE– A survey shall be made of the job site for hazards, such as untampered earth fills, ditches, debris, high tension wires, unguarded openings, and other hazardous conditions created by other trades. These conditions shall be corrected or avoided as noted in the following sections.

INSPECT ALL EQUIPMENT BEFORE USING– Never use any equipment that is damaged or defective in any way.

KEEP ALL EQUIPMENT IN GOOD REPAIR- Avoid using corroded equipment- the

strength of corroded equipment is not known.

INSPECT ERECT SCAFFOLDS DAILY- or at the beginning of every shift to be sure that they are maintained in safe condition.

NEVER USE EQUIPMENT FOR PURPOSES OR IN WAYS FOR WHICH IT WAS NOT INTENDED

CONSULT YOUR SCAFFOLDING SUPPLIER- NEVER TAKE CHANCES- Consult

manuals and instructions provided by the supplier; scaffolding is his business.