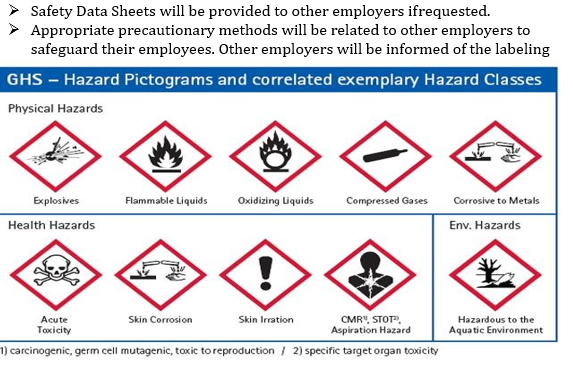

For one out of every four workers, working with hazardous chemicals is a daily experience. In the workplace, exposure is likely greater, concentrations higher, and exposure time longer. Thus, potential danger is greater on the job. We now have the Global Harmonized System. This includes standardized SDS’s that are used worldwide. The use of pictograms helps to describe the hazard no matter what language you speak.

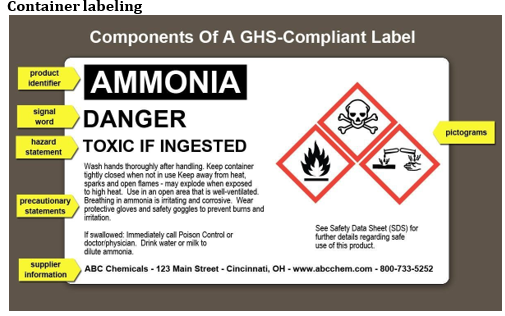

- The foreman will verify that all containers received for use will be clearly labeled as to the contents, note the appropriate hazard warning, and list the name and address of the manufacturer.

- The foreman in each work area will ensure that all secondary containers are labeled with either an extra copy of the original manufacturer label or with labels that have the identity and the appropriate hazard warning.

- Safety Management will review the company labeling procedures annually and update as required.

- Safety management is responsible for establishing and monitoring the company SDS Program. He or she will make sure procedures are developed to obtain the necessary SDS and will review incoming SDS’s for new or significant health and safety information. He / she will see that any new information is passed on to the affected employee. The following procedure will be followed when the SDS is not received at the time of initial shipment. The foreman will then notify safety manager and he / she will contact manufacturer of chemical.

- Copies of SDS for all hazardous chemicals in use will be kept in job trailers and / or 36

gang boxes.

- SDS will be readily available to all employees during each work shift. If an SDS is not available, immediately contact the foreman. To ensure SDSs are readily available in each work area, the safety manager will make certain that before a job begins, a SDS book is on site with all of the possible materials listed.

- When revised SDS’s are received, the safety manager will ensure that all job-sites receive the revised SDS’s.

- Discuss SDS that are in use during weekly Doggett Toolbox Safety Talks.

- Field Safety Specialist need to forward newly received/revised SDS to Corporate Safety for master filing.

Hazardous Non-routine tasks Periodically, employees are required to perform hazardous non-routine tasks. Example of non-routine task is confined space entry. Prior to starting such projects, each affected employee will be given information by the foreman about the hazardous chemicals he or she may encounter during such activity. This information will include specific chemical hazards, protective and safety measures the employee can use, and steps the company is using to reduce the hazards, including ventilation, respirators, presence of another employee and emergency procedures.

Informing Other Employers Working in Close Proximity

The foreman has the direct responsibility to provide other employers with information about hazardous chemicals their employees may be exposed to on a jobsite, including suggested precautions for the employees. Jobsite supervisor is required to obtain information about hazardous chemicals used by other employers that employees of this company may be exposed.

The following procedures will be used to inform other employers who have employees who may be exposed to hazardous chemicals use by employees of this company:

- A list of known hazardous chemicals used by our employees will be located in the front of the SDS book. Further information on each chemical may be obtained by reviewing SDS’s located at the job trailer / gang-box.

- Chemicals not already on the list are added to the list within thirty days of introduction into the work place. To ensure that the chemical is added in a timely manner, the following procedure will be followed. As soon as the SDS is obtained, the responsible party adds the SDS to the SDS book and numbers the table of contents appropriately.

- Employers shall provide employees with effective information and training on hazardous chemicals in their work area at the time of their initial assignment, and whenever a new physical or health hazard the employees have not previously been trained about is introduced into their work area. Information and training may be designed to cover categories of hazards (e.g., flammability, carcinogenicity) or specific chemicals. Chemical-specific information must always be available through labels and material safety data sheets.

- Employees shall be informed of any operations in their work area where hazardous chemicals are present; and, the location and availability of the written hazard communication program, including the required list(s) of hazardous chemicals, and material safety data sheets required by this section.