There is no doubt, tools, hand and powered, enable us to be more efficient and productive. Unfortunately, the power and efficiency also can pose serious risk of injury or death. Too often, tragedy occurs before steps are taken to search out and avoid or eliminate tool-related hazards.

Hand Tools

Hand tools attribute to a many types of injuries like lacerations, smashed fingers, etc. Box cutters are a tool designed to open up boxes not skin wires. Use the right tool for the job!

Hand tools include anything from axes to wrenches. The greatest hazards posed by hand tools are misuse and improper maintenance. Tool hazards include:

- Using a chisel as a screwdriver may cause the tip of the chisel to break. Hitting you or other employees

Tools are such a common part of our lives that it is difficult to remember that they may pose hazards. All tools are manufactured with safety in mind but, tragically, a serious accident often occurs before steps are taken to search out and avoid or eliminate tool-related hazards.

In the process of removing or avoiding the hazards, workers must learn to recognize the hazards associated with the different types of tools and the safety precautions necessary to prevent those hazards.

| Hand tools are non-powered. They include anything from Hacksaws to electrician knife. The greatest hazards posed by hand tools result from misuse and improper maintenance. Some examples: Using a screwdriver as a chisel may cause the tip of the screwdriver to break and fly, hitting the user or other employees.If a wooden handle on a tool such as a hammer or an axe is loose, splintered, or cracked, the head of the tool may fly off and strike the user or another worker.A wrench must not be used if its jaws are sprung, because it might slip.Impact tools such as chisels, wedges, or drift pins are unsafe if they have mushroomed heads. The heads might shatter on impact, sending sharp fragments flying. |  |

Doggett’s supervisors are responsible for the safe condition of tools and equipment used by employees, but you have the responsibility for properly using and maintaining tools.

Doggett’s supervisors should caution employees that saw blades, knives, or other tools be directed away from aisle areas and other employees working in close proximity.

Appropriate personal protective equipment, e.g., safety goggles, gloves, etc., should be worn due to hazards that may be encountered while using portable power tools and hand tools.

Safety requires that floors be kept as clean and dry as possible to prevent accidental slips with or around dangerous hand tools.

Around flammable substances, sparks produced by iron and steel hand tools can be a dangerous ignition source. Where this hazard exists, spark-resistant tools made from brass, plastic, aluminum, or wood will provide for safety.

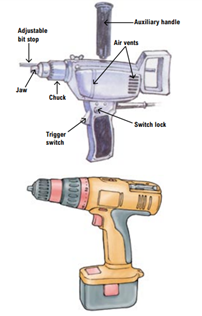

Power tools can be hazardous when improperly used. There are several types of power tools, based on the power source they use: electric, pneumatic, liquid fuel, hydraulic, and powder- actuated.

Employees should be trained in the use of all tools – not just power tools. They should understand the potential hazards as well as the safety precautions to prevent those hazards from occurring.

| The following general precautions should be observed by power tool users: Never carry a tool by the cord or hose.Never yank the cord or the hose to disconnect it from the receptacle.Keep cords and hoses away from heat, oil, and sharp edges.Disconnect tools when not in use, before servicing, and when changing accessories such as blades, bits and cutters.All observers should be kept at a safe distance away from the work area.Secure work with clamps or a vise, freeing both hands to operate the tool.Avoid accidental starting. The worker should not hold a finger on the switch button while carrying a plugged-in tool.Tools should be maintained with care. They should be kept sharp and clean for the best performance. Follow instructions in the user’s manual for lubricating and changing accessories.Be sure to keep good footing and maintain good balance.The proper apparel should be worn. Loose clothing or jewelry can become caught in moving parts.All portable electric tools that are damaged shall be removed from use and tagged “Do Not Use.” |  |

Hazardous moving parts of a power tool need to be safeguarded. Belts, gears, shafts, pulleys, sprockets, spindles, drums, fly wheels, chains, or other reciprocating, rotating, or moving parts of equipment must be guarded if such parts are exposed to contact by employees.

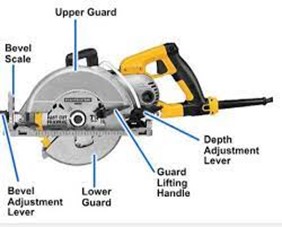

| Guards, as necessary, should be provided to protect the operator and others from the following: point of operation,in-running nip points,rotating parts, andflying chips and sparks. Safety guards must never be removed when a tool is being used. For example, portable circular saws must be equipped with guards. An upper guard must cover the entire blade of the saw. A retractable lower guard must cover the teeth of the saw, except when it contacts the work material. The lower guard must automatically return to the covering position when the tool is withdrawn from the work. |  |

Powered abrasive grinding, cutting, polishing, and wire buffing wheels create special safety problems because they may throw off flying fragments.

| PRE-Operation: Task (e.g., drawings, instructions, specifications, etc.) is clearly understood. PPE: gloves, eye protection (safety glasses & shield), hearing protection, protective clothing, face mask. Never remove guard. Ensure the appropriate disk is correctly in place. Ensure work piece is securely clamped. Ensure appropriate guarding is in place on grinder. Identify ON/OFF switch. Operation: Only use as per directions in user Manual. Check that the disk runs ‘true’ and does not wobble. Keep hands clear of work piece and away from disk. Turn off grinder at power point before changing the disk. Ensure guarding is in place before re-starting grinder. Ensure machines have been isolated from power sources before being cleaned, adjusted, maintained, or repaired. Post Operation: Switch off grinder before removing waste material from the bench. Ensure disk is still in good condition before putting away. |  |

Powder-actuated tools operate like a loaded gun and should be treated with the same respect and precautions. In fact, they are so dangerous that they must be operated only by specially trained employees.

Operators must be trained and certified prior to operating powder actuated tools. Operators shall have certification card with them at all times. Safety precautions to remember including the following:

These tools should not be used in an explosive or flammable atmosphere.

- Before using the tool, the worker should inspect it to determine that it is clean, that all moving parts operate freely, and that the barrel is free from obstructions.

- The tool should never be pointed at anybody.

- The tool should not be loaded unless it is to be used immediately. A loaded tool should not be left unattended. Unattended means out of your sight. Especially where it would be available to unauthorized persons.

- Hands should be kept clear of the barrel end. To prevent the tool from firing accidentally, two separate motions are required for firing: one to bring the tool into position, and another to pull the trigger. The tools must not be able to operate until they are pressed against the work surface with a force of at least 5 pounds greater than the total weight of the tool.

- If a powder-actuated tool misfires, the employee should wait at least 30 seconds, then try firing it again. If it still will not fire, the user should wait another 30 seconds so that the faulty cartridge is less likely to explode, than carefully remove the load. The bad cartridge should be put in water.

Suitable eye and face protection are essential when using a powder-actuated tool.

The muzzle end of the tool must have a protective shield or guard centered perpendicularly on the barrel to confine any flying fragments or particles that might otherwise create a hazard when the tool is fired. The tool must be designed so that it will not fire unless it has this kind of safety device.

All powder-actuated tools must be designed for varying powder charges so that the user can select a powder level necessary to do the work without excessive force.

If the tool develops a defect during use it should be tagged and taken out of service immediately until it is properly repaired.